The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

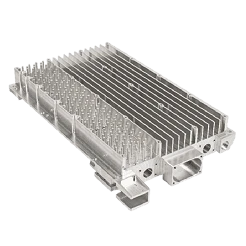

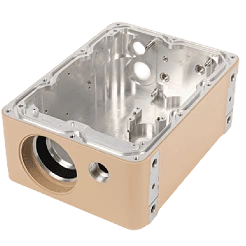

Calip Group, a specialist in precision engineering, focuses on the production of complex, high-value parts through advanced CNC milling and turning techniques. By enhancing the value of metal and integrating the latest technologies, we meet the demanding requirements of modern industries.

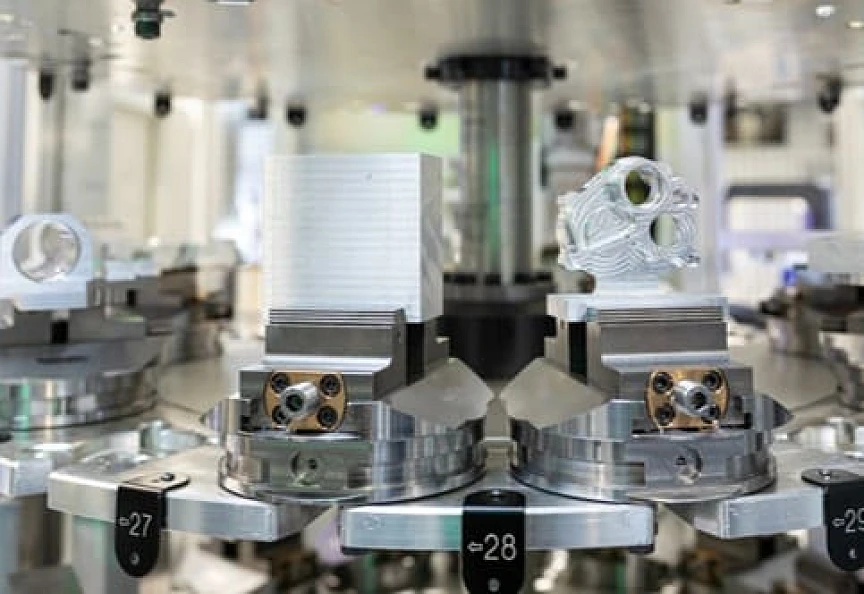

Calip Group stands out for its ability to machine complex, high-precision technical parts from all types of metals and alloys, including the most demanding materials. Thanks to 3-, 4- and 5-axis CNC machining centres and state-of-the-art turning machines, we produce both solid billet parts and reworked castings.

We integrate advanced processes such as grinding, electrical discharge machining (wire and die-sinking), industrial painting and deburring under binocular or camera inspection. With full control of the entire production chain, from surface treatment to final assembly, we guarantee our clients flawless dimensional quality and consistent reliability.

Calip Group’s know-how is backed by advanced machining capabilities, with 3-, 4- and 5-axis CNC centres operating around the clock.

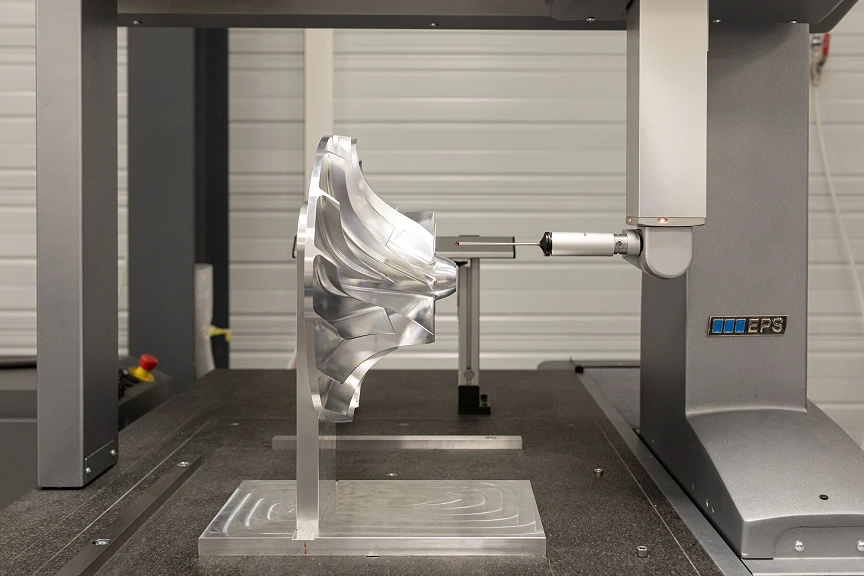

Our facilities allow continuous 5-axis and 4-axis milling up to 600 mm³, as well as 3-axis milling of large parts up to 3000 x 800 x 800 mm. In turning, we machine up to Ø 600 mm for lengths up to 1500 mm.

Thanks to our integrated R&D office, we design and manufacture custom tooling perfectly suited to each project's requirements. This ability to combine design, innovation and performance ensures full control of your industrial processes, from single parts to series production.

Complex parts

Calip Group specialises in machining tight-tolerance complex parts for critical applications in constrained environments

Advanced technology

Our latest-generation CNC machines deliver optimal precision across a wide range of metals and alloys.

Full production chain control

From machining to surface treatment and final assembly, we integrate every step to ensure full traceability and consistent quality.

Innovation and R&D

Our ongoing R&D investments and dedicated prototype workshops enable us to meet the specific needs of the most demanding industries.