The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

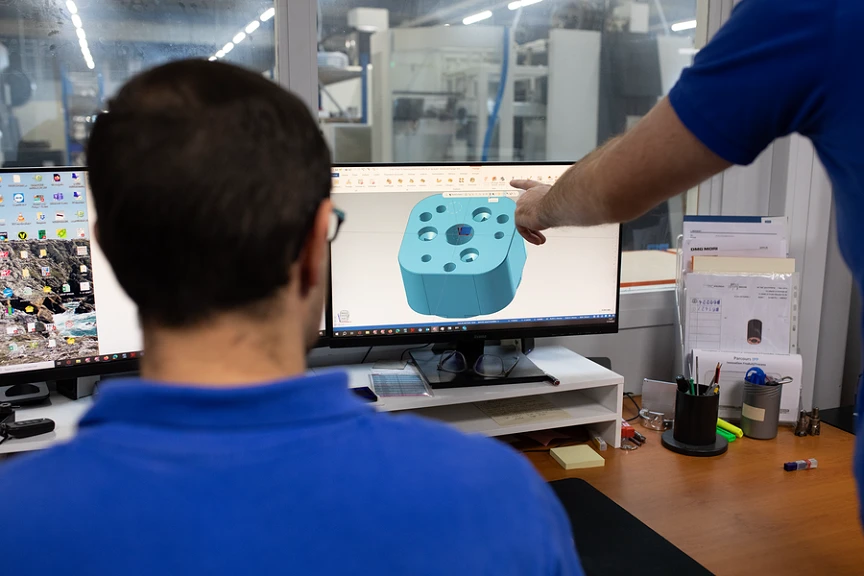

At Calip Group, every high-precision mechanical part is the result of collective effort. Our teams are involved in every stage of manufacturing—from CAD/CAM design to final metrology, including machining, setup, maintenance, assembly, finishing, and logistics.

Supporting roles such as HR, accounting, purchasing, methods, sales, and order administration ensure the quality, efficiency, and performance of our entire organization.

This synergy of skills enables Calip Group to meet the strictest industrial standards, delivering integration-ready parts on time and in compliance with all specifications.

The CNC setter is responsible for configuring CNC machine tools to ensure compliant production from the first part. They install tools, adjust parameters, modify programs if needed, and carry out initial checks.

This job requires a high level of technical skill, excellent blueprint reading, and full mastery of the machines. At Calip Group, our setters play a key role in production efficiency and in the quality of complex parts.

The methods technician defines the most suitable manufacturing processes to produce a part, optimizing time, cost, and quality. They write process sheets, select tools and machines, and formalize technical documentation.

This role is strategic, acting as a bridge between design and the workshop. At Calip Group, our methods technicians support each industrial project with precision to ensure smooth, efficient, and compliant production. .

The industrial metrology inspector checks the dimensional conformity of machined parts using high-precision measuring tools. They ensure that each part complies with the tolerances specified in the drawings.

This role is essential to guarantee the quality and reliability of mechanical parts. At Calip Group, our metrology experts are involved at every key step of the process, working closely with production and client requirements.

The assembler plays a vital role in the production chain. Based on technical drawings or work instructions, they assemble machined components, perform mechanical assembly, make necessary adjustments, and handle final finishes to ensure a compliant, functional product ready for delivery or integration.

This job requires precision, dexterity, autonomy, and attention to detail. Screwing, fitting, crimping, or bonding operations vary depending on the parts and assemblies. At Calip Group, our assembly and finishing technicians work closely with production and quality teams to deliver reliable, robust assemblies that meet each client’s technical requirements.

Their role ensures the final step of a rigorous process, where the quality of the end product is in their hands

At Calip Group, the success of each project depends on a diverse range of complementary roles.

Supporting production, our administrative assistants coordinate logistics and documentation, while maintenance technicians ensure equipment availability. The logistics team manages the smooth flow of materials and finished products from storage to shipping.

Support services play a strategic role as well : the purchasing team ensures the quality and competitiveness of supplies, sales administration (ADV) manages order processing, accounting monitors the company's financial health, human resources recruit, support, and retain talent, and the sales team builds client relationships and develops markets.

Other specialized roles strengthen our organization daily, making each project a collective success. And many more professions contribute every day to Calip Group’s achievements.