The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

Calip Group, an expert in high-precision mechanical assembly, supports its clients in delivering technical sub-assemblies ready to integrate into complex systems.

With advanced integration expertise, full production chain know-how, and an agile organisation based on lean manufacturing principles, we guarantee reliable, traceable solutions that meet the most stringent industrial requirements.

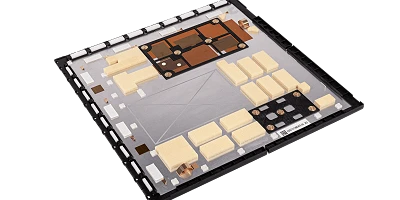

We integrate and assemble components from machining, sheet metal, aluminium profiles, technical plastics and electronics.

Our teams are involved from the design stage to develop tailor-made integration solutions, all the way through to the delivery of complete assemblies ready to be integrated into our clients’ systems.

We master a wide range of industrial assembly processes:

Integration also relies on a robotic adhesive dispensing system, ensuring precise, repeatable applications within tight tolerances.

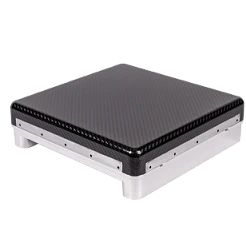

Calip Group operates a 250 m² cleanroom specifically designed for the integration of sensitive or high-value mechanical sub-assemblies, including for cleanroom-grade applications.

This controlled atmosphere environment meets the requirements of the aerospace, defense, nuclear, robotics and medical sectors, with a rigorously organised lean workflow and separated entry/exit circuits to ensure full traceability, efficiency and quality compliance.

Our in-house design office and prototyping workshops provide agile, responsive support, particularly for small or medium production runs involving complex projects.

Integration and assembly are just one part of a fully controlled production chain at Calip Group. From complex part machining and surface treatment to painting, dimensional inspection and logistics, we ensure a coherent, end-to-end industrial approach.

Thanks to integrated project management, we oversee every step while optimising lead times, costs and quality. Our scope includes:

Operating in critical sectors such as aerospace, defense, robotics and medical, we provide agile and reliable support from design to industrialisation.

Precision assembly

Calip Group delivers integration of complex mechanical sub-assemblies with flawless quality, thanks to full control of critical processes.

Advanced technologies

Our advanced equipment, such as robotic adhesive dispensers, ensures reliable, repeatable assembly adapted to sensitive or tight-tolerance components.

Controlled assembly environment

Calip Group manages the entire production chain up to final assembly, ensuring consistent quality and responsiveness to customer demands.

Integrated production management

Calip Group handles the full value chain, from raw part to mounted sub-assembly, for a complete and high-performance industrial solution.