The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

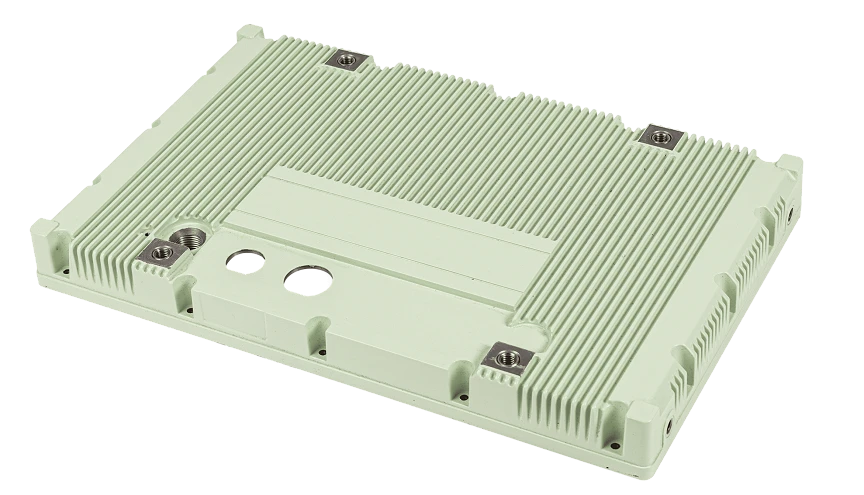

Calip Group, known for its expertise in precision machining, provides rework services for raw cast parts (milling and turning) in aluminium.

Thanks to advanced processes and strict quality controls, we ensure excellent dimensional compliance for the most demanding industrial sectors.

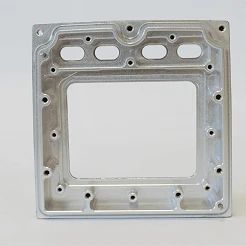

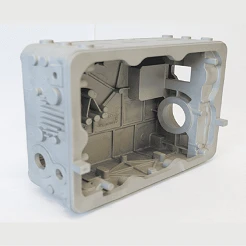

Calip Group machines raw cast parts made of aluminium, cast iron, steel, or special alloys, finishing them with 3-, 4-, or 5-axis CNC machining.

These operations turn molded parts into high-performance technical components that meet the strict standards of aerospace, automotive, defense, and robotics industries.

The precision achieved during rework enables us to reach complex geometries, controlled surface finishes, and perfect dimensional conformity.

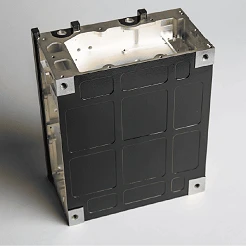

We also integrate additional operations such as 3D dimensional inspection, deburring, painting, and mechanical assembly.

At Calip Group, foundry rework is part of a comprehensive industrial process that covers all stages of machining and manufacturing:

• Receipt and inspection of raw castings

• High-precision CNC machining

• Surface treatments

• Industrial painting

• Mechanical assembly

• Final quality control

Our in-house design office and prototype workshops also allow us to get involved upstream, from the design phase of the cast parts, to optimize their geometry based on machining constraints and production goals.

Whether for one-off, small, or medium-size production runs, we offer a turnkey solution that is reliable, sustainable, and tailored to the most demanding industrial requirements.

Complex cast part machining

Reworking of raw aluminium, cast iron, steel or alloy parts with micrometric precision.

Multi-axis technology

3-, 4- and 5-axis CNC machining centers for complex and irregular raw surfaces.

Integrated quality control

3D measurements, dimensional validation, and full traceability of all operations.

Complete production chain

From foundry to finished produc t: controlled machining, surface treatment, assembly, and delivery.