The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

Calip Group designs and manufactures custom industrial tooling, taking into account your technical, quality and ergonomic requirements.

These solutions make it possible to validate a concept, simulate assembly, choose the right materials, and precisely define dimensions, weight and tolerances before product industrialisation.

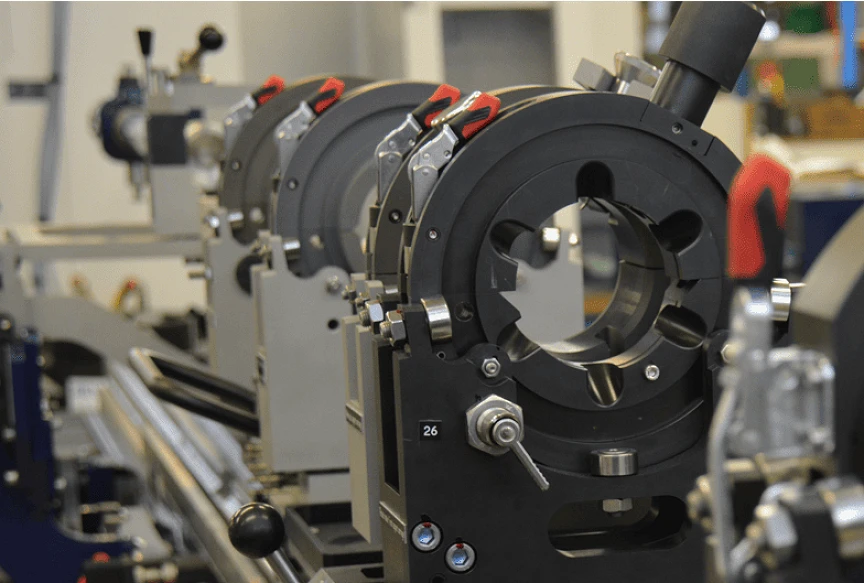

Calip Group designs, manufactures and adjusts custom high-precision tooling, including machining fixtures, control jigs, cutting tools and handling equipment.

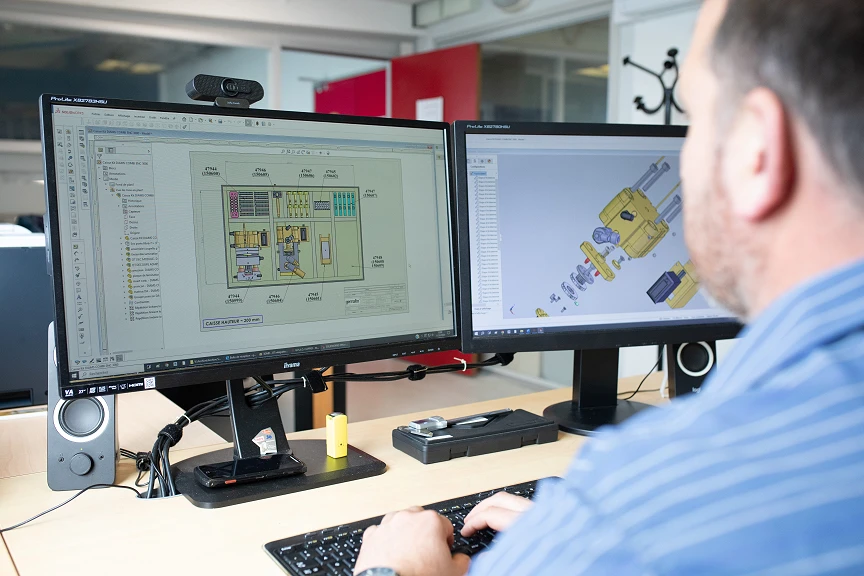

Our in-house design office, equipped with advanced CAD software, develops solutions perfectly adapted to your parts, production rates and working environments.

We produce both single-unit and small-series tooling, for prototyping as well as production, with a high level of finish and reliability.

These technical tools are essential for:

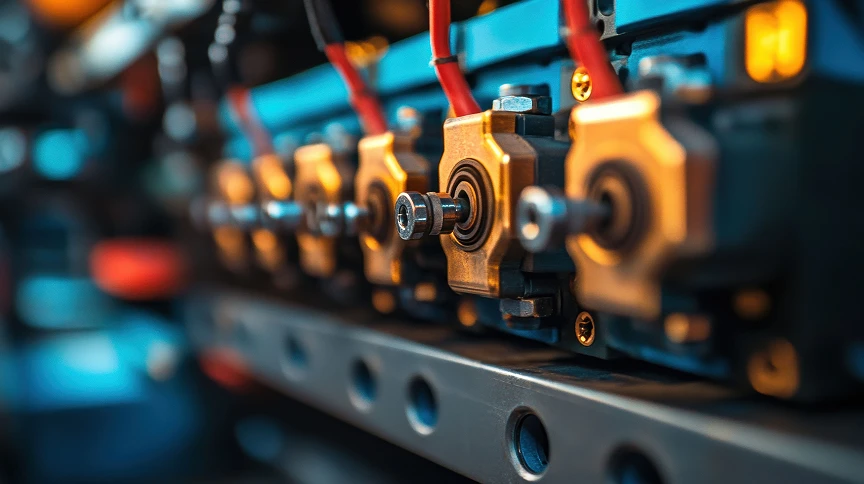

Calip Group manages the entire tooling production cycle, from design and machining to inspection, assembly and delivery.

Our industrial setup integrates technical procurement, heat treatment, coatings and logistics, ensuring smooth project management, short lead times and strong reactivity.

Our tooling solutions aim to:

Thanks to this integrated approach, we meet the requirements of demanding sectors such as aerospace, defense, green mobility and medical.

Custom design

3D study and modelling of tooling adapted to technical, quality and ergonomic constraints.

Integrated manufacturing

In-house machining, fitting, assembly and inspection for full process control

Product validation & prototyping

Tools to test, adjust and validate dimensions, materials, weight and assembly processes.

Responsiveness & versatility

Fast lead times, single units or small batches, tooling for machining, assembly or inspection.