The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

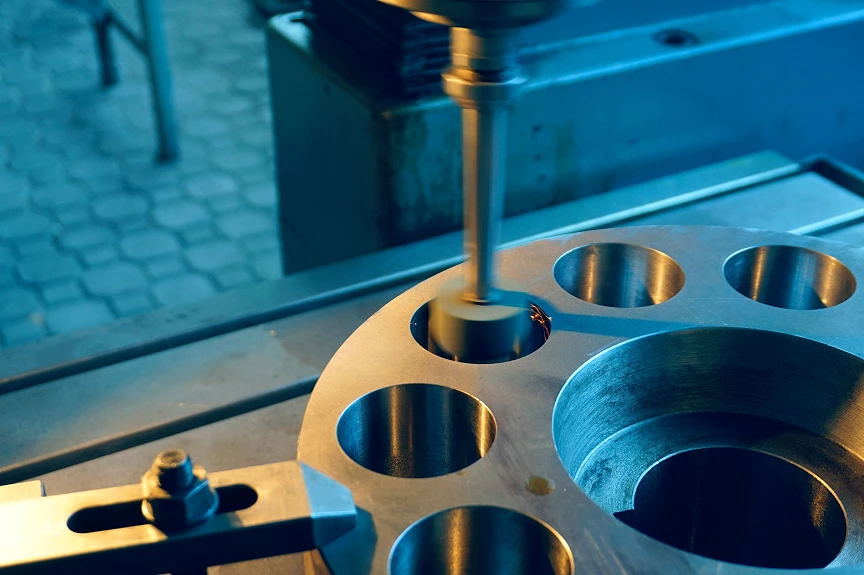

Calip Group masters surface and profile grinding to ensure flawless surface quality, strict dimensional tolerances and geometric conformity — even on the most complex parts.

We deliver high-level finishes tailored to the demands of assembly, contact or sliding surfaces, for the most demanding industrial sectors.

Calip Group performs high-precision surface grinding to guarantee perfect flatness, essential for contact, support or sliding surfaces.

These operations meet extremely tight tolerances, particularly in high-requirement sectors such as aerospace, defense and precision mechanics.

Integrated into the overall production flow, our surface grinding services ensure quality, geometric consistency and on-time delivery.

We carry out profile grinding on complex mechanical parts, including radii, shoulders, tapered profiles or non-standard shapes, with micrometric accuracy.

This technique is ideal for ensuring repeatability, dimensional conformity and a flawless finish.

Thanks to specialised equipment and proven expertise, we handle complex profile grinding on all types of materials.

Surface grinding

Grinding of flat surfaces for support, contact or sliding functions, with strict tolerance compliance.

Profile grinding

Machining of complex profiles, radii or shoulders with micrometric precision.

Finishing on hard materials

Grinding after heat treatment on hardened steels, carbides, stainless steel and more.

Quality and inspection

Rigorous monitoring using 3D inspection tools to validate geometric compliance.