The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

Calip Group masters electrical discharge machining (EDM) processes, including wire cutting and sinking, for the production of complex mechanical parts in hard, treated or conductive materials.

These precision technologies allow extremely tight dimensional tolerances while ensuring excellent surface finish — even for intricate internal geometries. Essential for high-requirement applications, EDM is widely used in defense, aerospace, medical and tooling industries.

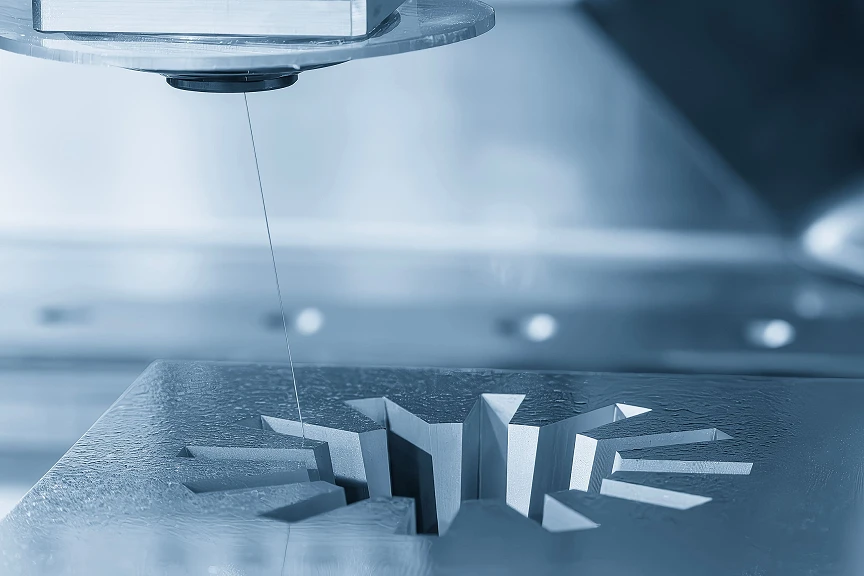

Wire electrical discharge machining (EDM wire cutting) is a high-precision process perfectly suited to complex technical parts.

Using a very fine conductive wire, precisely guided by CNC, this non-contact cutting method allows for:

It ensures exceptional dimensional stability and smooth finishes.

Wire cutting is widely used for tooling as well as in high-demand sectors such as aerospace, defense, medical and robotics, where precision, dimensional integrity and surface quality are critical.

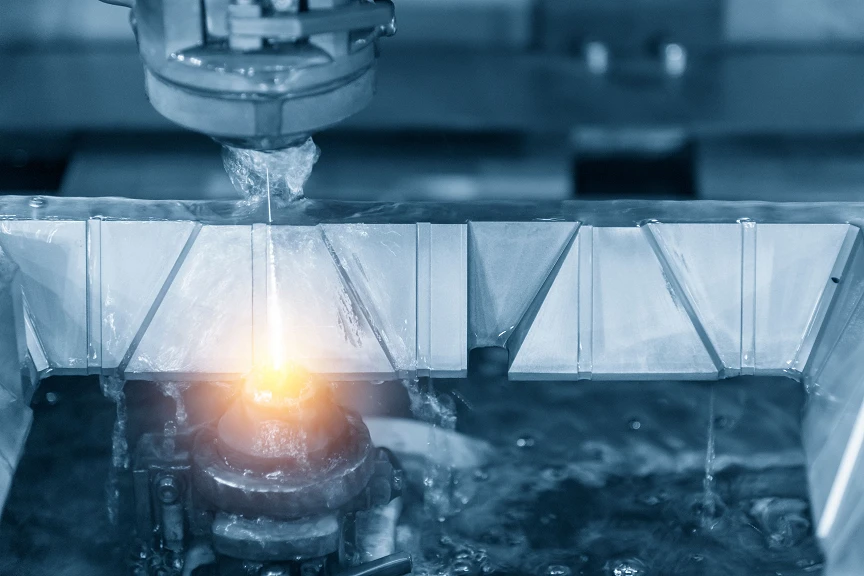

EDM sinking is a high-precision process that uses custom-designed electrodes to shape complex internal features.

This non-contact technology enables:

Sinking is compatible with a wide range of conductive materials, including hardened steels, stainless steel, titanium and carbides. It is especially suitable for manufacturing moulds, cutting tools, forming electrodes or high-precision mechanical components.

Integrated into our production chain, this process ensures optimal repeatability, consistent quality and reduced reworking — for reliable, well-controlled production.

High-precision wire cutting

Machining of complex contours and sharp corners using fine-diameter wire on multi-axis CNC machines.

Sinking for technical cavities

Precision shaping of internal forms with custom electrodes — ideal for moulds and tooling.

Compatibility with hard materials

Controlled machining of treated conductive metals: hardened steels, carbides, stainless steel, titanium — with consistent precision and finish.

Integrated, controlled production

EDM is fully integrated into Calip Group’s industrial workflow, ensuring certified quality, shorter lead times and reactivity for high-value parts.