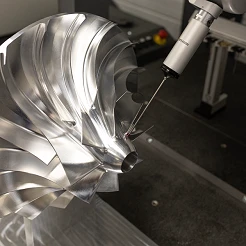

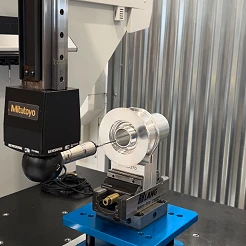

Calip Group is a recognised industrial player known for its expertise in high-precision CNC machining and multi-technology assembly. We operate from tooling design to final integration, mastering every stage of the production chain to ensure performance, responsiveness and full compliance with the most stringent requirements.

This commitment is rooted in deeply held values: transparency that fosters trust, authenticity expressed through respect for our employees, customers and partners, rigour inseparable from industrial excellence, and a strong commitment to talent development — a true driver of innovation and performance.

Thanks to this demanding and human-focused industrial culture, Calip Group supports the most advanced sectors such as aerospace, space, defense, transportation, nuclear and medical, with certified, sustainable and tailor-made solutions.