The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

The news from SPEMA and MEFIC will now be available on this website, following their integration into Calip Group.

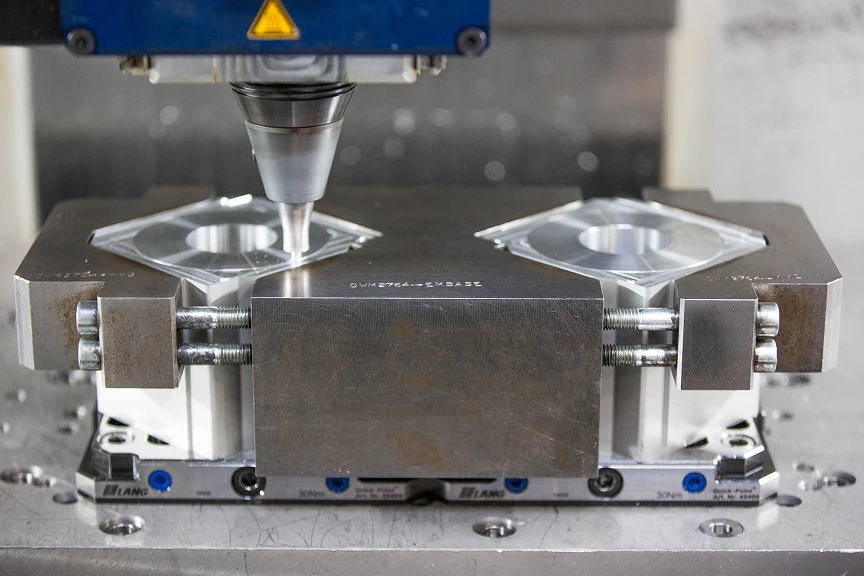

FSW is based on a mechanical mixing process through friction, which joins materials in a plastic state. It generates very little heat, avoids deformation and eliminates common welding defects such as porosity, cracks or inclusions. The process offers:

As part of a continuous improvement approach, Calip Group collaborates with specialised institutes such as Institut de Soudure and CETIM, and is a member of Printing in Bourges.

These partnerships strengthen our technological monitoring, certification levels and ability to offer ever more advanced solutions. Our FSW expertise is part of a long-term industrial quality and innovation strategy.

Solid-state process

A weld performed without filler metal or material fusion, reducing the risk of deformation, cracking or porosity. Ideal for high-value aluminium alloys.

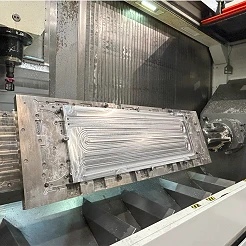

Excellent mechanical strength

FSW joints offer high mechanical resistance and long-term reliability, even under significant structural stress.

Environmentally responsible

A clean, energy-efficient process with no gas emissions or polluting consumables. FSW supports sustainable industry and low-carbon manufacturing.

Industrial applications

FSW is ideal for joining complex aluminium components in aerospace, defense, mobility and embedded electronics sectors.